New DOE Mandates Efficiency Standard for Circulators

Are you ready?

An industry-wide mandate effective May 22, 2028, applying to all manufacturers.

The U.S. Department of Energy has established new minimum efficiency standards that require a transition from AC induction motor circulators to high-efficiency ECM technology across the industry.

View DOE Rulemaking below:

What to expect

Today

AC circulators remain available as the industry prepares for the transition.

Through May 2028

AC circulators will continue to be manufactured during the transition period.

What’s Next

ECM circulators become the compliant standard moving forward.

Find Your ECM Replacement

Replacement Guide

Start with your current AC model to identify the right ECM replacement.

Need Help With Your Project/Application?

Let’s Take a Look at Your System

What’s Changing – FAQs

Department of Energy (DOE) Ruling on AC Induction Motors for Circulators

As of May 22, 2028, manufacturers will no longer be permitted to produce standard efficiency circulators that use AC induction motors. This ruling from the DOE is part of a broader effort to increase energy efficiency and reduce carbon emissions in the HVAC an plumbing industries. The transition to more efficient, advanced circulators with ECM (Electronically Commutated Motor) technology is already underway and will continue to expand in the coming years.

What is the DOE Ruling About?

The DOE’s ruling mandates that as of May 22, 2028, all new circulators must use high-efficiency motors such as ECMs, instead of the traditional AC induction motors. This change is aimed at reducing energy consumption and improving overall system performance.

Why is This Change Happening?

The primary goal of this ruling is to improve energy efficiency in heating, ventilation, and air conditioning (HVAC) systems. AC induction motors, while reliable, are less efficient than newer ECMs that are designed to adjust their speed based on system demand, leading to significant energy savings over time and a reduction in greenhouse gas emissions.

What Products are Affected?

Standard AC induction motor circulators are being phased out and replaced by high-efficiency ECM circulators.

Who is Impacted?

All circulator manufacturers, along with engineers, contractors, and building owners who specify, install, or service circulators.

What Are ECMs?

ECMs are a more advanced type of motor that uses electronic controls to regulate motor speed and efficiency. Unlike AC induction motors, ECMs provide variable-speed control, which allows circulators to adjust to the specific needs of a system, improving both performance and energy efficiency. They use permanent magnets to reduce the overall power consumption while maintaining the same level of performance.

What Can Customers Expect in the Transition?

- More Options: The industry has been introducing circulators with ECMs over the past decade, and more models with different sizes and performance capabilities will be introduced before the 2028 deadline. You can expect a wider range of choices to meet your specific needs.

- Improved Energy Efficiency: ECM circulators are significantly more energy-efficient than their AC counterparts. This will translate into lower operating costs for customers, especially in applications that require variable flow or constant demand.

- Compatibility: While ECM circulators are highly efficient, they may require different installation or setup considerations compared to traditional AC circulators. It’s important to consult with your HVAC professional to ensure compatibility with your current systems.

- Ongoing Support and Upgrades: Manufacturers are working to ensure that replacement circulators with ECM technology will meet or exceed the performance of existing models. Additionally, service and support for older systems will continue through the transition period.

What Should I Do Now?

- Stay Informed: As the deadline approaches, make sure to stay updated on product offerings, installation guidelines, and available rebates or incentives.

- Plan for the Future: If you are purchasing or replacing circulators, now is the time to start considering ECM models that meet or exceed the upcoming DOE standards. While AC motors are still available, they will no longer be produced after May 2028. Switching to ECMs sooner rather than later will offer long-term cost savings.

- Check System Compatibility: If you’re thinking about replacing existing circulators or upgrading your system, consult with an HVAC professional (rewrite to audience) to ensure that the ECM circulators will be compatible with your existing infrastructure.

Will This Change Affect My Current Circulator?

No. If you already have a circulator with an AC induction motor installed the DOE ruling will not require you to replace it before 2028. However, you may want to consider upgrading to an ECM circulator before the deadline to take advantage of energy savings and avoid discontinued standard efficiency products.

How Will This Affect Pricing?

While ECM circulators tend to have a higher initial cost than AC induction models, their increased energy efficiency will result in lower operating costs over time. In many cases, the energy savings can offset the higher upfront cost. Additionally, there may be rebates or other incentives made available through your state or local utility company to help with the transition.

What Will Manufacturers Do to Support This Transition?

Manufacturers are committed to supporting the industry through this transition by:

- Expanding the variety of ECM circulators available, including more sizes and performance options.

- Providing training and resources to HVAC professionals for proper installation and maintenance.

- Offering clear guidance on how existing systems can be retrofitted or replaced with ECM circulators.

How Will the Transition Affect HVAC Professionals?

HVAC professionals will need to adapt to the new technology by:

- Gaining knowledge of ECM installation, configuration, and troubleshooting.

- Understanding the differences between AC induction motors and ECM circulators to provide the best solutions for customers.

- Staying up to date on any new regulations, certifications, or training programs related to ECMs.

How do I know I am buying a DOE compliant energy-efficient circulator?

See info on the HI Energy Rating Label, or visit https://tacocomfort.com/leader-in-high-efficiency-circulators

The Trump administration stopped the rulemaking from going into effect during his first term, will that happen again?

No, the rulemaking fell outside the timeframe of a rulemaking which could be changed by executive order. It will go into effect on May 22, 2028.

Where can I find more information about the state and utility incentive programs offered for high-efficiency circulator pumps?

You can find detailed information through the HI Incentive Database and on our microsite. We also recommend checking directly with your local utility, as programs can vary by region. Most incentive programs are applied as an instant discount at the wholesaler counter at the time of purchase, rather than through a mail-in rebate.

Will this rulemaking cover products sold into Canada too?

Although Canada has not officially announced an effective date, they have in the past harmonized with almost every DOE rulemaking within the HVAC space and we expect they will do the same for circulators on the same May 22, 2028 effective date as the United States.

Does the US DOE circulator efficiency standard align with the European efficiency standard?

No, the energy efficiency metrics/ratings are based on different testing methodologies, have different rating nomenclatures (CEI in US vs EEI in EU), and different compliance thresholds. The EU standards also do not include circulators used in domestic hot water recirculation systems, where the US regulations do not exempt any circulators based on application.

Where Can I Learn More?

For more information, visit https://tacocomfort.com/leader-in-high-efficiency-circulators

or consult with your HVAC contractor. As the transition to ECM technology progresses, industry resources, product manuals, and installation guides will be readily available.

Why ECM

ECM circulators offer measurable efficiency and performance benefits compared to traditional AC models.

Future-ready compliance

Meets DOE minimum efficiency standards moving forward.

Energy efficiency

Lower energy consumption compared to traditional AC circulators.

Variable-speed performance

Adjusts output based on system demand for improved operation.

Lower operating costs

Reduced energy use can translate into long-term savings.

AFFECTED CIRCULATORS

Showing all 16 results

-

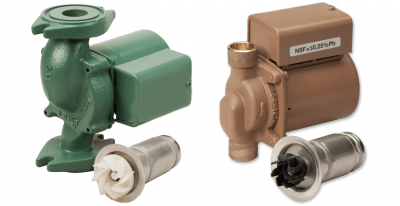

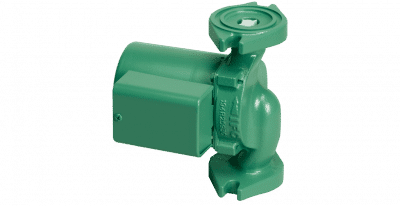

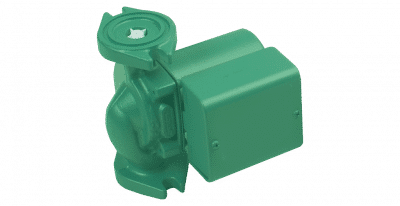

00 Series Cartridge Circulators

-

00 Series Variable Speed Circulators

-

00R-IFC Radiant Heating Circulator

-

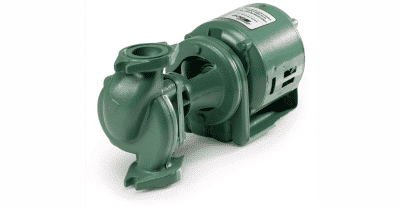

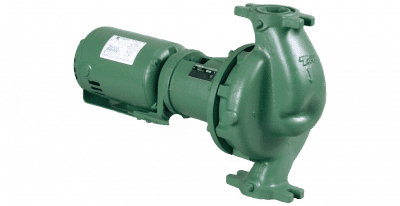

110-120 Series In-Line Circulators

-

121-138 Series In-Line Circulators

-

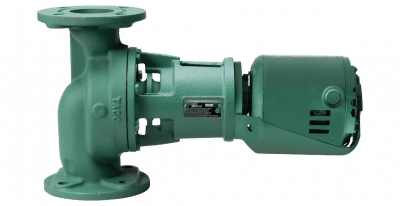

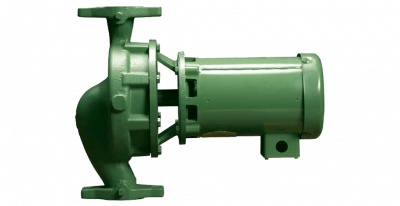

1600 Series In-Line Pumps

-

1900 Series Close-Coupled In-Line Pumps

-

2400 Series High Capacity Circulators

-

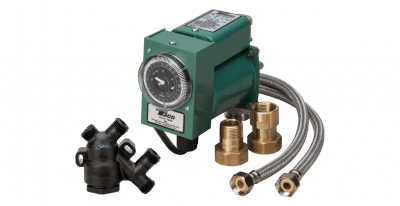

Hot-Link System

-

LoadMatch Circulators

-

LoadMatch System

-

LOFlo Injection Pumping System

-

Plumb n’ Plug Wet Rotor Circulator

-

Priority Zoning Circulator

-

SmartPlus Hot Water Recirculation