PC700 Boiler Reset Control

Performance Data

Boiler Start — 35 to 150°F (2 to 66°C) Factory: 70°F (21°C)

Outdoor Start — 35 to 85°F (2 to 29°C) Factory: 70°F (21°C)

Boiler Design — 70 to 220°F (21 to 104°C) Factory: 190°F (88°C)

Outdoor Design — -60 to 32°F (-51 to 0°C) Factory: 10°F (-12°C)

Boiler Minimum — Off, 80 to 180°F (Off, 27 to 82°C) Factory: 140 °F (60°C)

Differential — Auto, 2 to 42°F (Auto, 1 to 24°C) Factory: Auto

WWSD — 35 to 100°F, Off (2 to 38°C, Off) Factory: 70°F (21°C)

Units — °F, °C Factory: °F

Features

- Control — Microprocessor PI control; This is not a safety (limit) control.

- Packaged weight — 1.3 lb. (580 g)

- Dimensions — 4-3/4” H x 2-7/8” W x 7/8” D (120 x 74 x 22 mm)

- Approvals — CSA NRTL /C; Meets ICES & FCC regulations for EMI/RFI

- Ambient conditions — Indoor use only, 32 to 105°F (0 to 40°C), < 90% RH noncondensing.

- Power supply — Class 2, 24 V ±10% 50/60 Hz 3 VA (Powered by Taco -Exp Control) Relays — 24 V (ac) 5 A 1/6 hp, pilot duty 240 VA

Sensors Included:

- NTC thermistor, 10 kΩ @ 77°F (25°C ±0.2°C) ß=3892

- Outdoor Sensor M 2036 and Universal Sensor 071.

Applications

- Hot Water Heating Systems

- Closed Cooling Circuits

- Air Conditioning Systems

- Hydronic Heating & Cooling

- Water/Glycol concentrations up to 50%

- Solar / Geothermal

Models & Related Documents

Case Studies

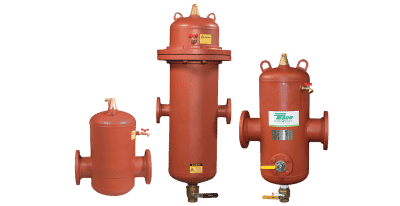

Taco Comfort Solutions

Service & Support