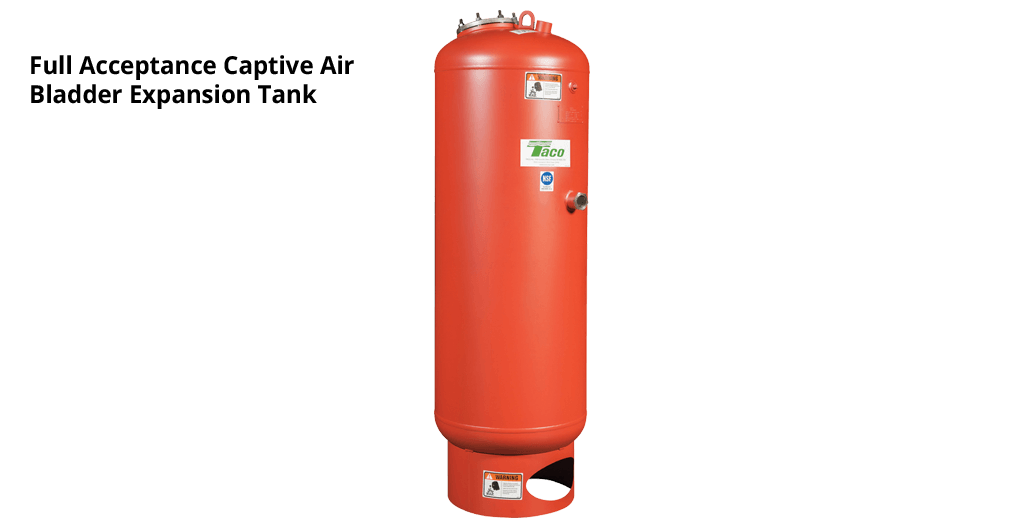

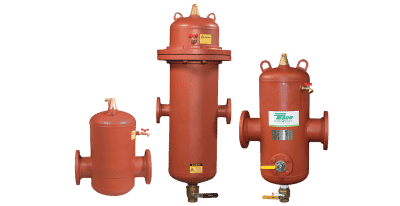

CA Series Expansion Tanks

Performance Data

Capacity: 23-3962 Gallons (90-15000 Liters)

Diameters: 20-72″

Height: 29-282″

Working Pressure: 125,150,175, 250, 300 (PSI) Higher Pressures Optional

Max. Operating Temp.: 240°F (Optional 280°F)

Features

- Designed, constructed and tested to ASME Section VIII, Div. 1 requirements.

- Heavy Duty butyl rubber bladder

- Full acceptance bladder design (field replaceable)

- Carbon steel construction (SS system connection optional, SS construction optional)

- All fabrication done in house

- Computerized selections to ensure fast and easy design

- National Board Registration

- CRN registration (optional)

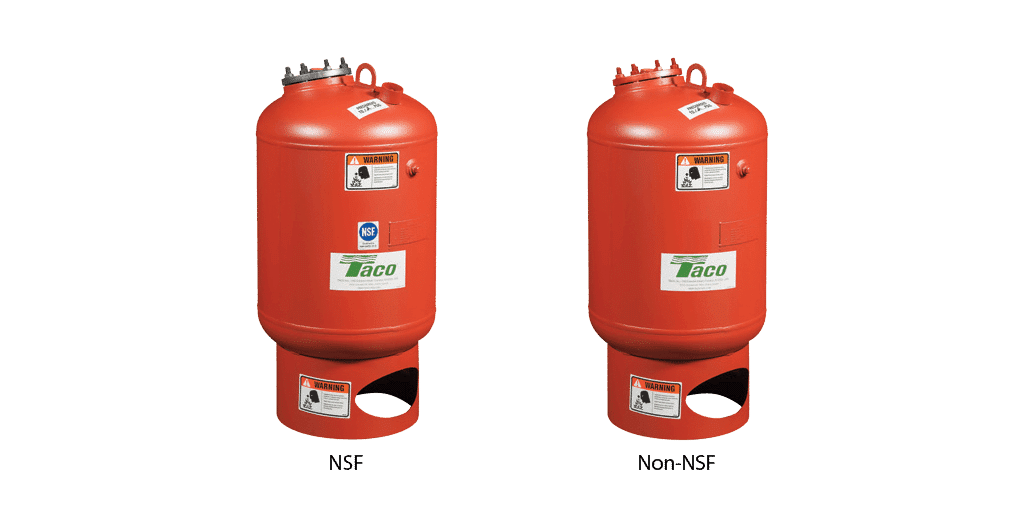

- NSF/ANSI 61-G Certified and Listed (Optional)

Applications

- LoadMatch® Systems

- Commercial, Institutional, Industrial Hydronic Systems

- Larger Systems

- Systems where reliability and lower maintenance costs are important

- Potable Water (optional)

Taco Comfort Solutions

Service & Support