Williston Northampton School

Case Study

Williston Northampton School

Easthampton, Massachusetts

– Case Description

As part of the largest, most comprehensive fundraising campaign in its 167 year history, The Williston Northampton School, an independent, co-ed college prep school in western Massachusetts, purchased and renovated a private home located just adjacent to its campus and added a dorm wing and additional faculty apartments to it. The school has over 500 enrolled students in grades 7 through 12, sixty percent of whom live on campus. The desire to provide more modern living space and consolidate the campus that has grown through the years has prompted the school to establish new housing space for both boarding students and faculty.

Summary

Architect:

Flansburgh Associates, Inc., Boston, MA

General Contractor:

Fontaine Bros. Inc., Springfield, MA

Consulting Engineers:

Robert W. Hall Consulting Engineers, Inc., Agawam, MA

Mechanical Contractors:

T.J. Conway Co., Springfield, MA

The Victorian-era building itself was converted into three faculty apartments. A student dorm for 32 students and two additional faculty residences were added as new construction. The entire project was on a $7 million fast track schedule that started in November of 2007 and concluded in September 2008 to coincide with the beginning of the school year. The new use 24,000 sq. ft. structure – now comprised of a total three faculty apartments and the student dorm – comes equipped for heating and cooling with Taco’s LoadMatch® single pipe hydronic system linked to a groundsource- heat-pump system tapping into fifteen underground wells at a depth of 350 ft.

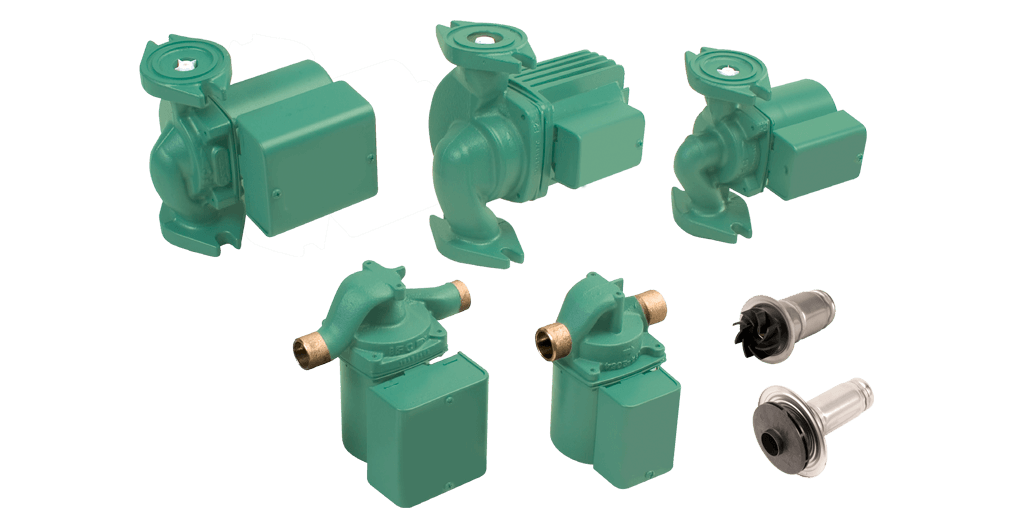

The Williston Northampton School had been first introduced by Taco to its LoadMatch system, which replaces control valves and most balancing valves with small, low KW wet rotor circulators on a closed loop, back in 2006-2007, when it upgraded the heating systems in several other campus dorms and faculty residences. Those buildings had either steam heat or electric heat and were constantly “too hot or too cold,” according to Jeff Tannatt, the school’s physical plant director, who oversaw the conversion to a LoadMatch system coupled with Hydrotherm Kn-6 and GS 110 boilers. Tannatt says that control valves had been a “big source of problems, maintenance-wise” in those buildings prior to their conversion. Eliminating control valves with LoadMatch realized “big savings,” and the LoadMatch circulators were “easy to install and easy to maintain.” While Tannatt and his crew had accomplished the HVAC upgrade the first time around without outside assistance, the most recent renovation and 20,000 sq. ft. addition to the existing Victorian-era home involved architects and engineers and was completed by a local contractor, with the caveat that whatever final form the installed system took it would include the LoadMatch system.

Products

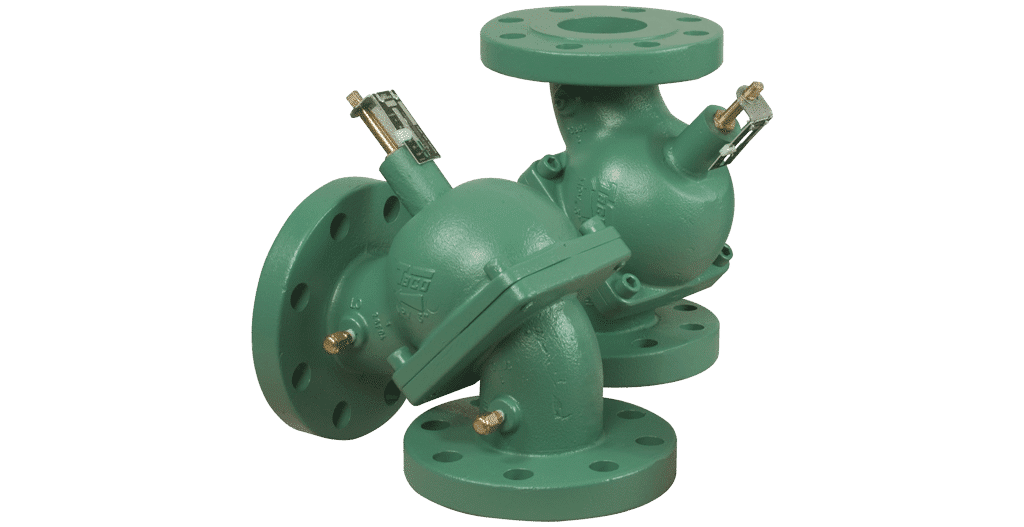

LoadMatch® System

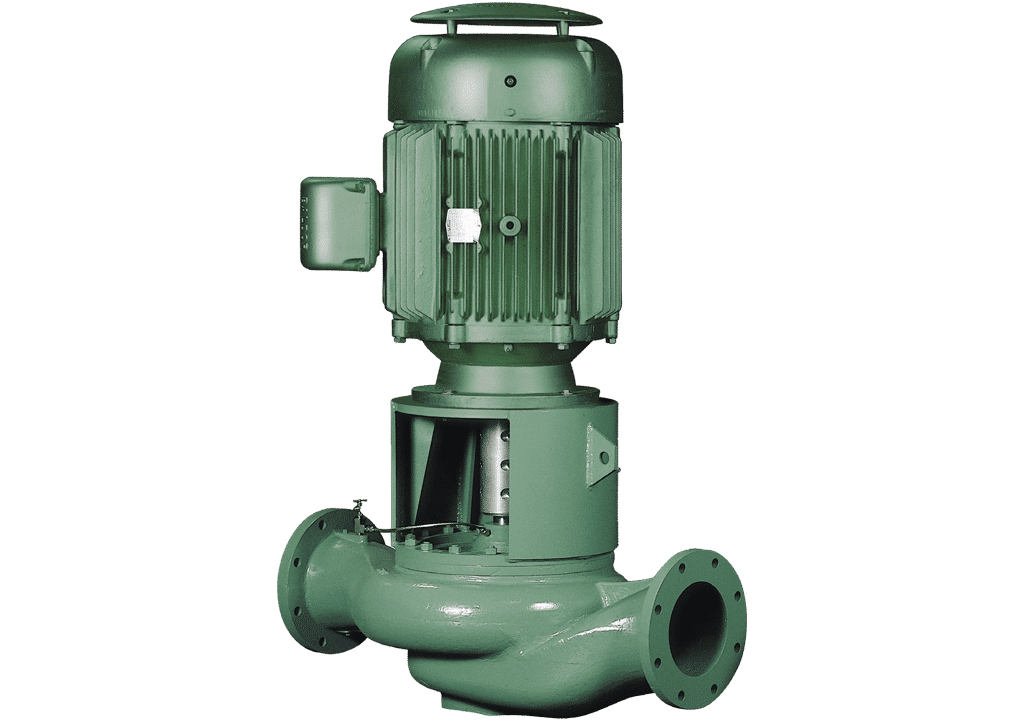

FI Series Base-Mounted End Suction Pumps

LoadMatch® Circulators

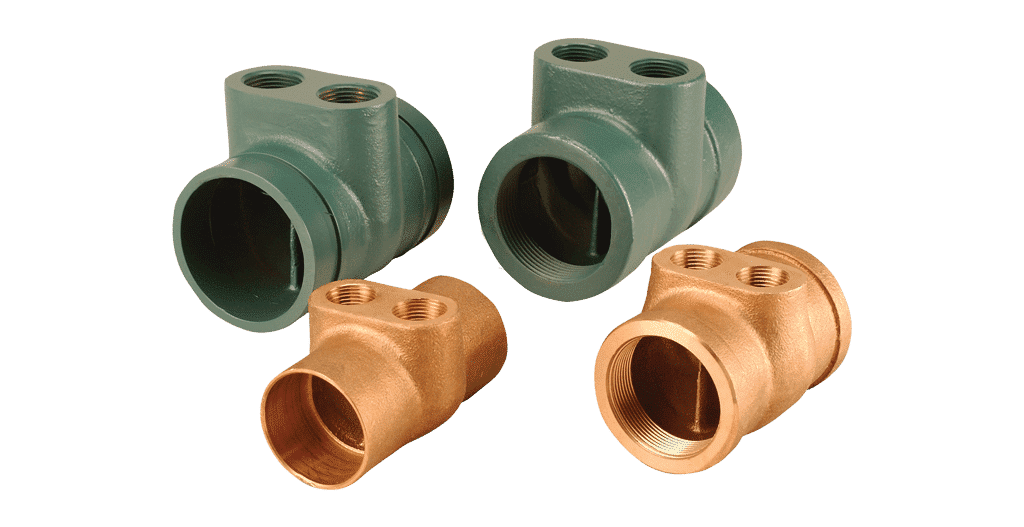

LoadMatch® Twin-Tee® Fittings

Final Result

“LoadMatch circulators are easy to maintain, and the system is very flexible. LoadMatch is a true single pipe system, one we’ll select again.”

—Sandy Lake

While Jeff Tannatt was a believer in the LoadMatch system from the first renovation/upgrade project, the system concept and design had to be introduced to both the engineering firm, Robert W. Hall Consulting Engineers, Inc. of Agawam, MA, and the installing contractor, T.J. Conway of Spring!eld, MA. They had been selected by the project architect, Flansburgh Associates of Boston, MA, and Fontaine Brothers of Springfield, MA, the general contractor. Neither had dealt with the LoadMatch system previously. “There was skepticism about it,” admits Marvin Blakley of T.J. Conway. A preliminary design for the system was provided by Taco using its proprietary HVAC System Solution (HSS) software, which lays out the total system and even does equipment sizing and load calculations automatically. Robert W. Hall project manager Sandy Lake finalized the system design using HSS.

Along with 37 LoadMatch circulators and accompanying Twin Tee fittings, the new HVAC system for the Williston Northampton School dorm and faculty apartments includes two 20-ton Florida Heat Pumps and two accompanying A.O. Smith hot water storage tanks for the vertical ground loop, and Carrier fan coil units and TAC thermostats for precise temperature control of each room. RBI Futera 3 gas-fired condensing hot water heaters provide abundant domestic hot water at 110º F. Chilled water temperatures on the loop range from 42º F to 50º F. As used in the first renovation project, PEX tubing substituted for copper pipe. SNE Building Systems of East Granby, CT provided EMS/BAS automated systems for the building.

Conway’s Blakley was surprised by the 40-50 percent savings realized in the reduction of piping and controls using LoadMatch. Based on The Williston Northampton School project experience, he and Lake both agree that LoadMatch is a win-win system. “With conventional systems you have little control over valves, which can be a big source of maintenance problems,” says Lake. “LoadMatch circulators on the other hand are easy to maintain, and the system is very flexible. LoadMatch is a true single pipe system, one we’ll select again.”