YOUR REPUTATION IS OUR BUSINESS

At Taco, your success is at the heart of everything we do. For over a century, we’ve built our reputation by protecting yours—delivering water-driven solutions that perform with precision, reliability, and confidence.

As a family-owned, women-led company, Taco combines innovation with integrity, offering high-efficiency heating, cooling, and plumbing systems engineered for real-world performance. From advanced circulators and control technology to intuitive design and selection software, every product is built to simplify your workflow and strengthen your results.

Whether you’re a contractor, engineer, or wholesaler, Taco is your trusted partner for peace of mind—backed by world-class training, responsive technical support, and a legacy of craftsmanship that keeps the industry moving forward.

PRODUCTS

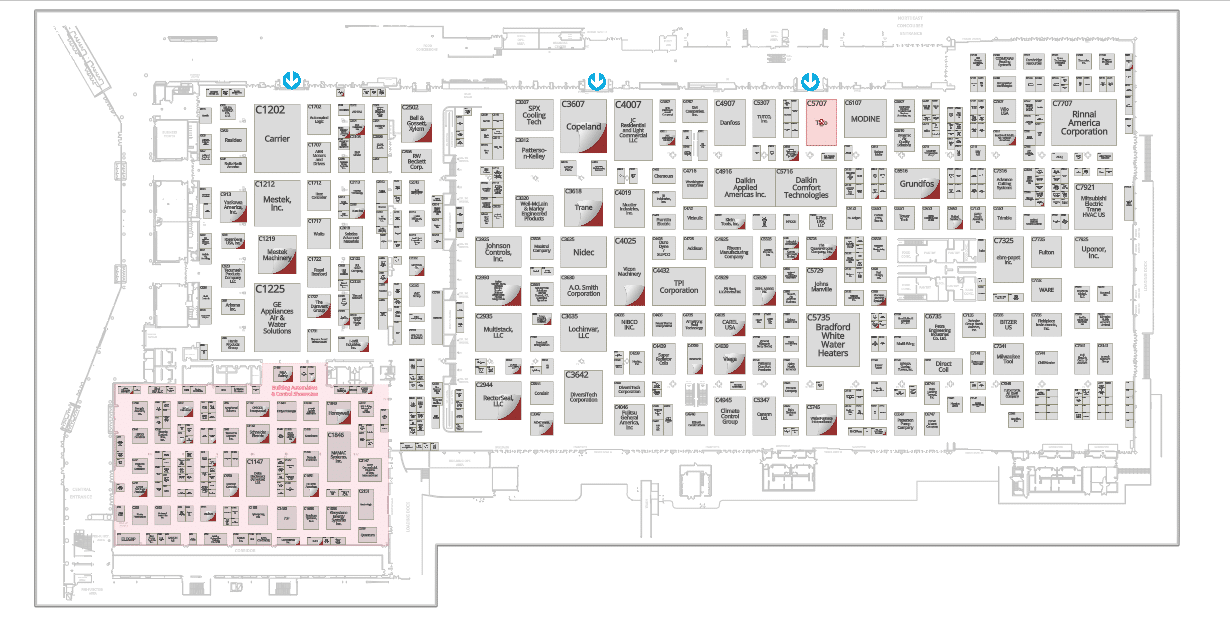

SKS Series SelfSensing Vertical Split-Coupled In-Line Pumps

- Upgraded mounted drives options, now available up to 125 HP

- Expansion of the existing range with the drive offering, fully integrated in configurator and with SKS,SKV, SCI, SFI pumps

- Large Pre-programmed drives offering, like Delta P, Delta T, Multi Pump control

- On the Skid at AHR:

- SKS Series Vertical Slip-Coupled In-Line Pump with 125 HP Drive

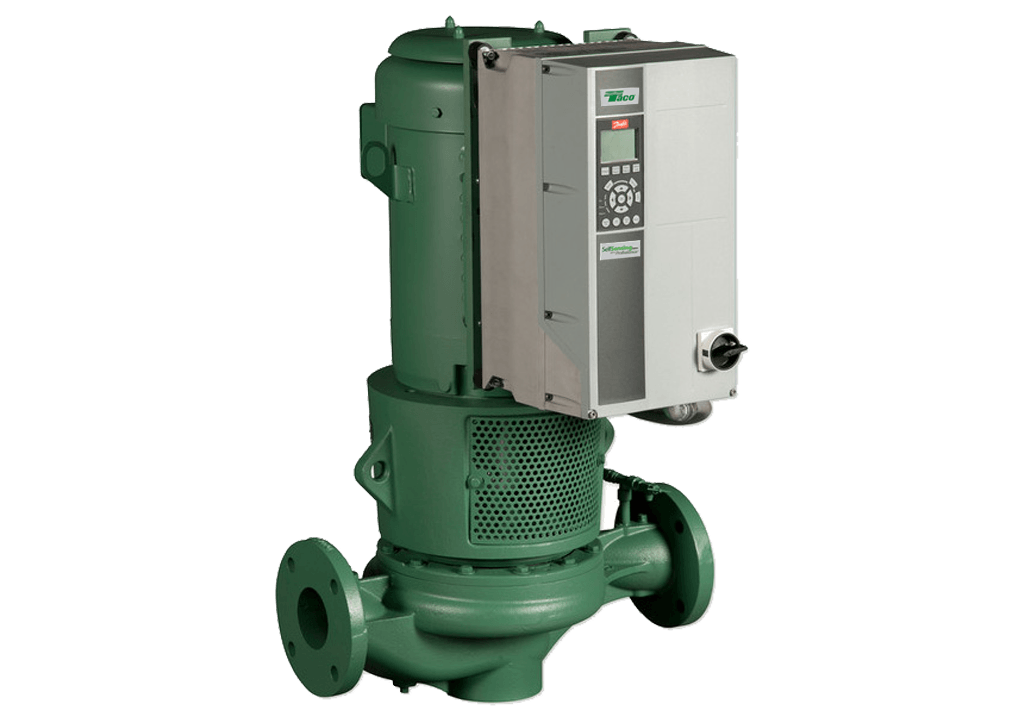

Compact HS Series Horizontal Split Case Pumps

- Compact Footprint, Full-Scale Performance: The Compact HS Pump is 50% smallerthan conventional HS Pumps while maintaining full hydraulic performance.

- Alignment and Grouting free design does not require a steel base plate coupling &coupling guard; therefore, alignment and grouting are eliminated, making installation &service simpler and faster.

- With best-in-class motor efficiency reaching 97.1%, a motor that not only meets butexceeds IE5 efficiency standards

- Reduced logistical costs. The Compact HS Pump’s stackable packaging size and 60%reduction in weight lower total logistics costs.

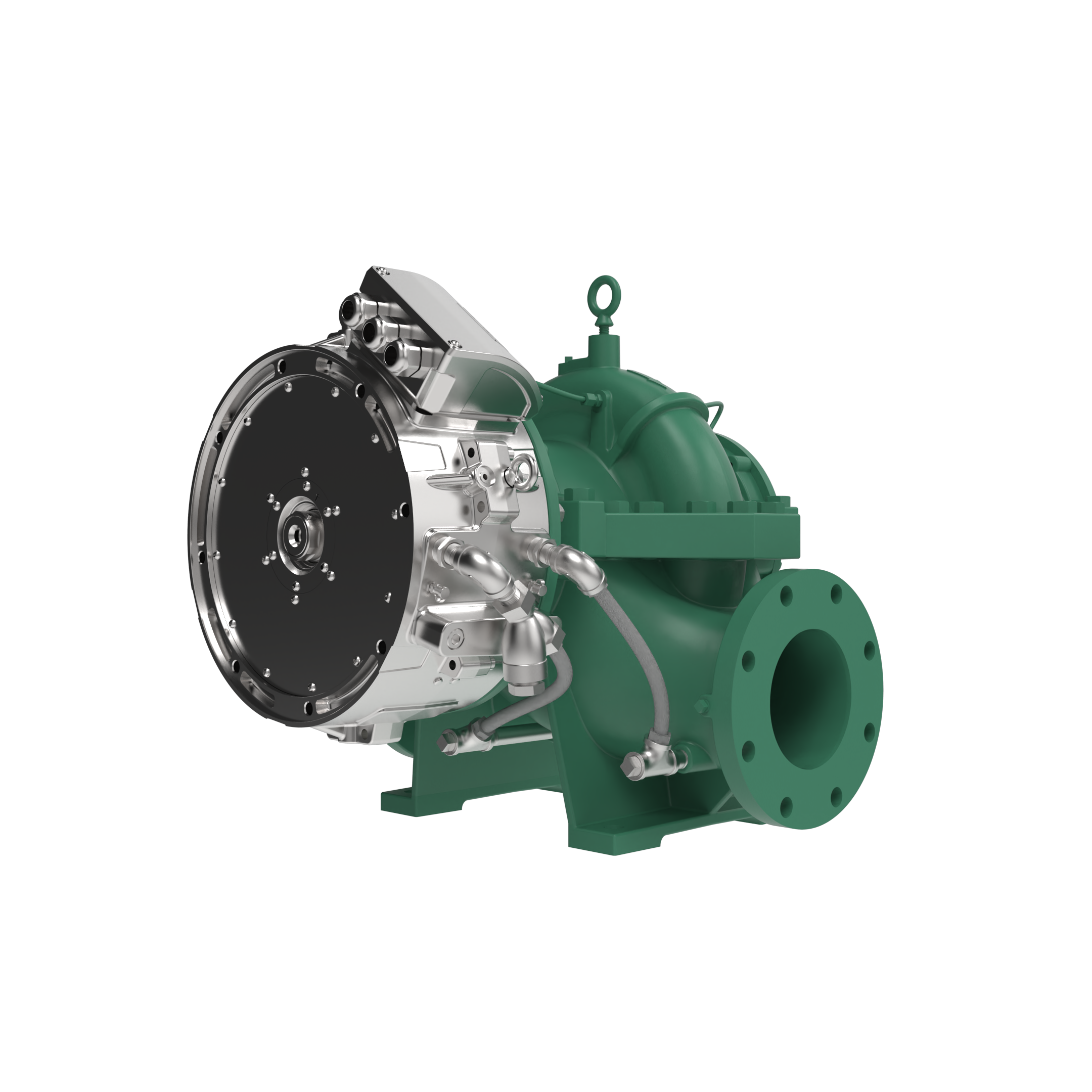

TridentBoost™ Booster Pump System

- Intuitive Touchscreen Control: A large color HMI touchscreen with guided startup and on-screen diagnostics simplifies navigation, speeds installation, and reduces downtime andservice costs.

- Energy-Efficient, Reliable Design: A fan-forced cooling system and updated control paneldeliver long-term reliability while meeting ASHRAE 90.1 standards to reduce energy use andoperating costs.

- Flexible Pump Configurations: A versatile skid design supports both end suction and verticalmulti-stage pumps for customizable application solutions.

- Low-Maintenance Installation: A no-gasket, field-configurable header and rotatable controlpanel enable quick modifications, simplified installation, and reduced maintenance over time.

- NSF-61 Listed

Thermal Energy Storage Tank

- Enhanced stratification through precise internal diffuser design

- CFD performance validation

- ASME section VIII, Div 1. design, construction, and testing.

- Factory Applications Support

CAF Series Flow-Through Expansion Tank

- Wisconsin Legislature

- Integrated safety with patent pending flow channeling head design

- Discourages Legionella and other bacterial growth

- Minimizes pressure loss, discourages short-cycling

- Available with sight glass for failure detection

- NSF/ANSI 61-G certified

- Retrofittable to meet ASHRAE Standard 188 on existing designs

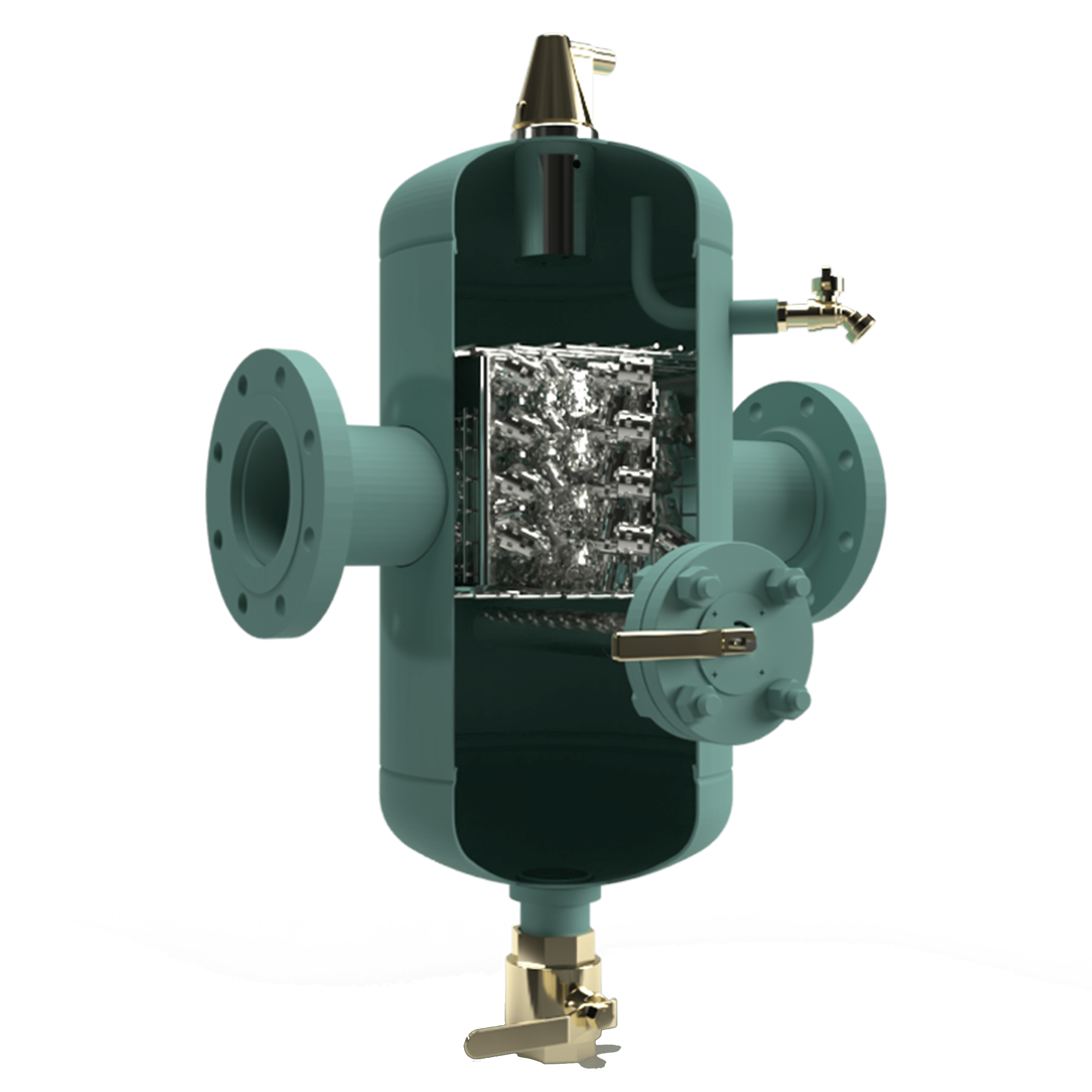

4900 Series® Air Separator w/Magnetic Dirt Separator

- Stainless steel pall ring coalescing media for optimal air and dirt removal

- Easy maintenance through Patented on/off magnet

- High-power neodymium magnets

- 2” full port blow down on 3” and larger models

- Reduced field installation and maintenance times

Custom Fabrication Tank

- In-house capabilities to design, fabricate, and test to your specific job requirements

- Customized variations of standard designs and unique one-offs

- Dedicated engineering support team

- All fabricated products are manufactured to ASME Section VIII, Div 1 requirements

PS/PA Series Plate & Frame Heat Exchanger

- Designed, constructed, and tested to ASME Section VIII, Div. 1 req.; U stamp provided

- Custom-designed and assembled to your specific heat transfer and hydraulic needs

- Built to last – 0.5mm thick plates for standard designs; 0.6mm plates for high-pressure designrequirements

- Corrosion-resistant 304/316 stainless steel & titanium heat transfer plates are available

- Working pressure 150-psi & 300-psi; higher pressures on request

- High-temperature gaskets available – NBR-HT rated to 284°F; EPDM-HT rated to 320 °F

NextGen Zone Controls

- Expandable to 20 Zoning Panels (120 zones if all are 6-zone panels)

- Built-in Post Purge and Pump exercise functions

- Modbus communication, 4 Programmable Outputs & Diagnostic lights for all outputs

- Additional space for wiring, both side & rear Knockouts, and more written zone space

- Upgradable PC800-5 option to add Indoor & Outdoor Reset Control

- Plus, more features are unlocked w/Taco Control Mobile App

0034ePlus ® ECM High-Efficiency Circulator

- 180 watts, 34 feet max head, 50 GPM max flow

- Designed for heating or hot water recirculation

- Cast iron or stainless-steel volute (NSF/ANSI 61 & 372 certified)

- Digital display with real-time feedback:

- Watts, GPM, Feet of Head, RPM

- Push button control with 5 operating modes:

- TacoAdapt™ self-adjusting proportional pressure

- Constant pressure – 5 settings

- Proportional pressure – 5 settings

- Min/Max fixed speed

- 0-10V & PWM

- BIO Barrier® & SureStart ®

0026e® ECM High-Efficiency Circulator

- 120 watts, 26 feet max head, 44 GPM max flow

- Designed for heating or hot water recirculation

- Cast iron or stainless-steel volute (NSF/ANSI 61 & 372 certified)

- 5 easy dial settings to match system requirements:

- TacoAdapt™ self-adjusting proportional pressure

- Constant pressure – 8 ft. Head, 16 ft. head

- Max fixed speed – 26 ft. head

- Min/Max fixed speed

- 0-10V DC & PWM

- BIO Barrier® & SureStart ®

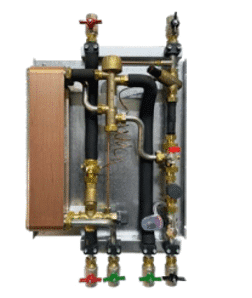

TacoTherm Fresh Nano2

- Preconfigured gas boiler replacement unit with a compact design

- On-demand, hygienic, decentralized DHW heating

- Reduction of the hygiene risk for drinking water heating

- Reduction of radiation losses as there is no DHW storage

- Demand-based energy billing

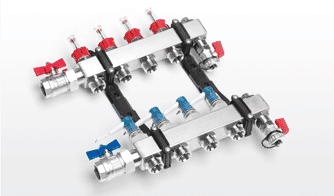

TacoSys Pro

- Next generation of Underfloor Heating System manifolds

- Reproducible hydraulic balancing thanks to the balancing valve with memory function

- Compact and space-saving with the smallest actuator valve on the underfloor heating market

- Reduce installation time and speed up commissioning as the actuators are pre-assembledbefore delivery

VT Series Vertical Turbine Pump

- Flows to 14,000 GPM

- Discharge Pressure to 800’ TDH

- Investment Cast 201SS Impellers

- Higher BHN compared to Bronze

- Better Surface finish

- Ductile Iron Bowls & Discharge Heads

- Custom Discharge Head & Column in house

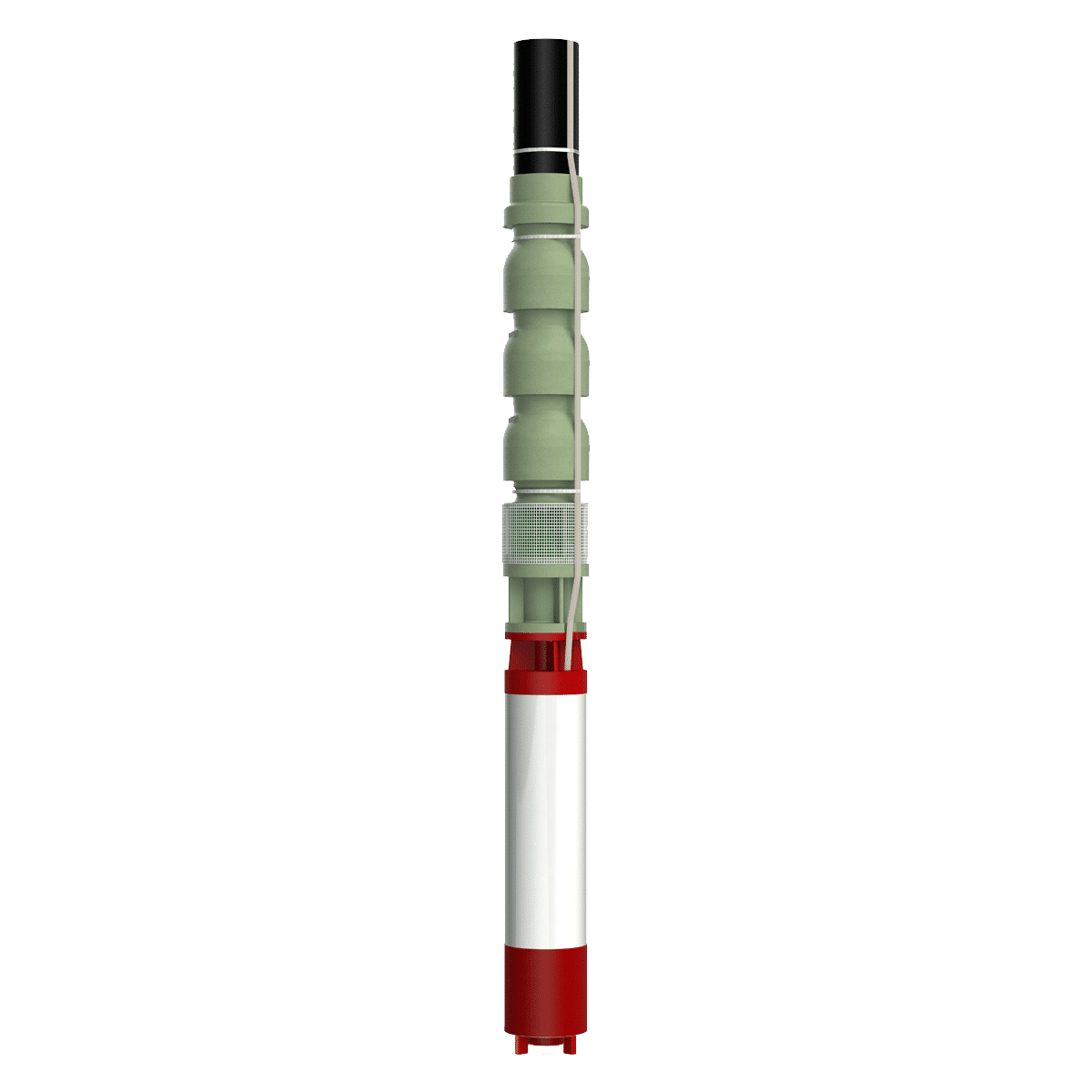

VT Series Vertical Turbine Submersible Pump

- 5” – 16” Bowl Diameters

- Flows 100 GPM – 5500 GPM

- The 201SS has the right combination of Carbon for High BHN compared to Bronze.

- Ductile Iron Bowls & Discharge Heads

PRESS RELEASES

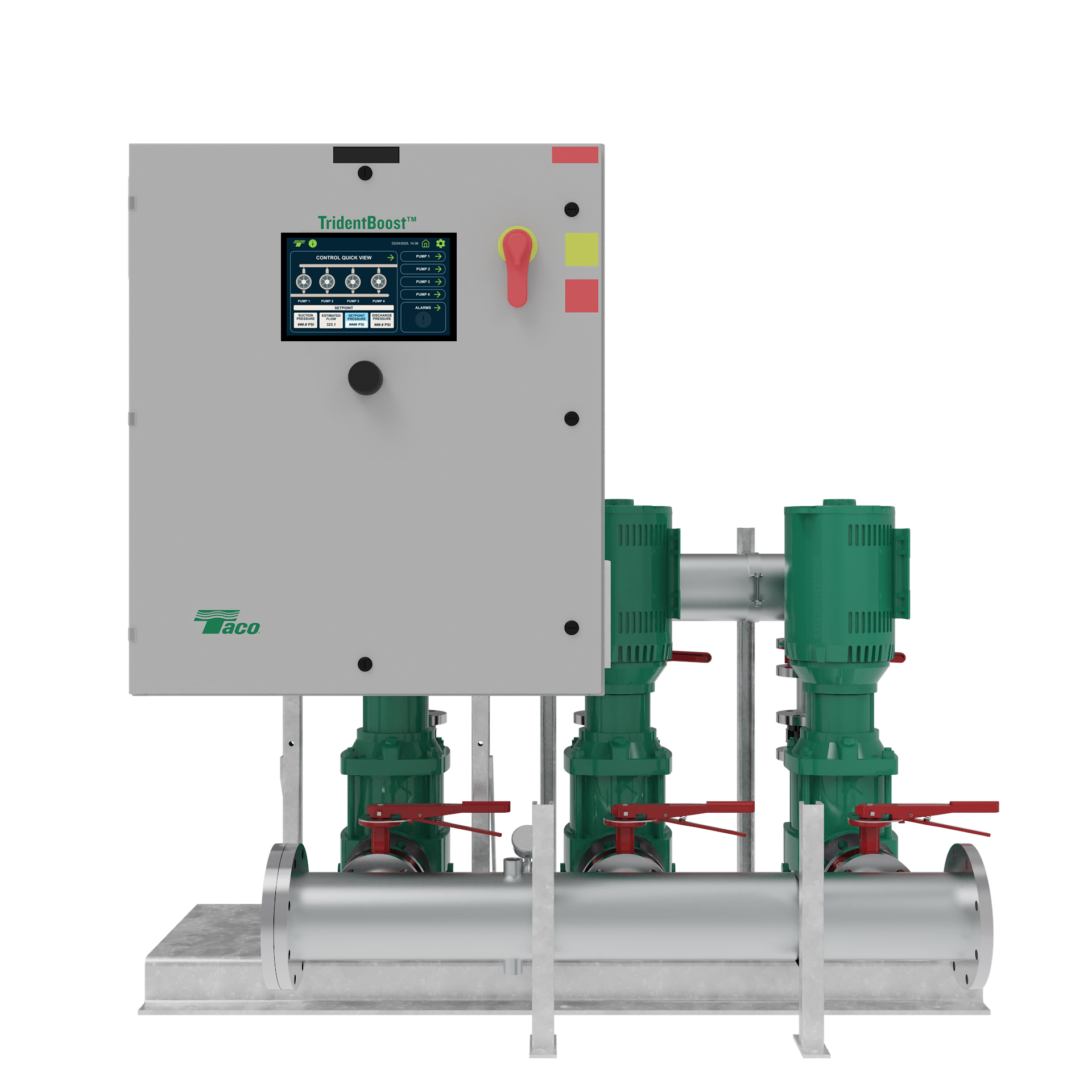

SHOW INFO

SHOW DATES & HOURS

Mon., Feb 2, 2026 > 10am-6pm

Tues., Feb 3, 2026 > 10am-6pm

Wed., Feb 4, 2026 > 10am-4pm

SHOW LOCATION

Las Vegas Convention Center

Central and South Halls

3150 Paradise Rd

Las Vegas, NV 89109