MISSION CRITICAL

Taco Comfort Solutions offers energy-efficient, Mission Critical Rated Products

The need for more efficient, liquid cooling designs has never been greater due to the ever-increasing power density of data centers, combined with rising energy costs. Our products help data center owners optimize their liquid cooling systems and decrease their maintenance costs and PUE.

Featuring upgraded materials of construction, our Mission Critical Rated Products help data centers increase their efficiency, reliability, and longevity.

— Dielectric fluid compatible

— Optimizes chiller performance to improve data center efficiency

— Stainless steel construction

— Customized thermal energy storage tank solutions

Data Center Industry Stats

Data centers require efficient cooling and air conditioning, accounting for 40% of total energy consumption.

In 2021, North America Revenue share was greater than 40%.

Choose Dependable Mission Critical Rated Products

Avoid costly downtime due to failures in your system by choosing the products you can count on for superior performance. Pick from 4 tiers of Mission Critical Rated Products that are built to withstand your systems requirements, giving you peace of mind.

Durable Multi-Purpose (MPT) and Buffer Tanks

- Designed and built to ASME standards

- Corrosion-resistant stainless steel construction

- BAS-friendly automatic blow-down valve compatible

- A convenient clean-in-place (CIP) system reduces maintenance costs and downtime

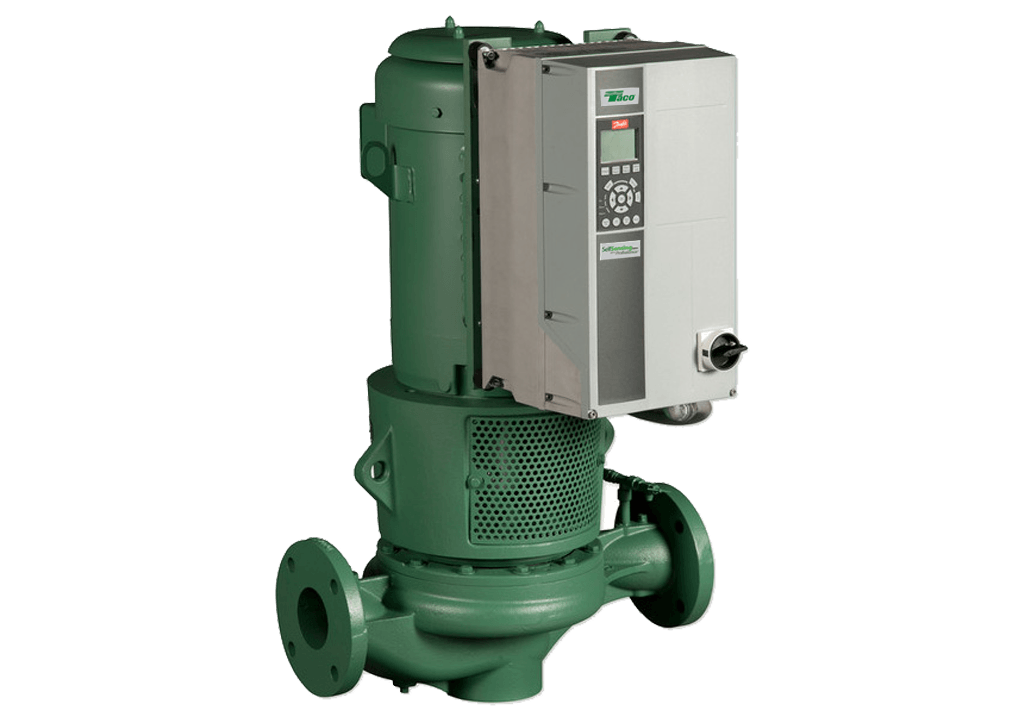

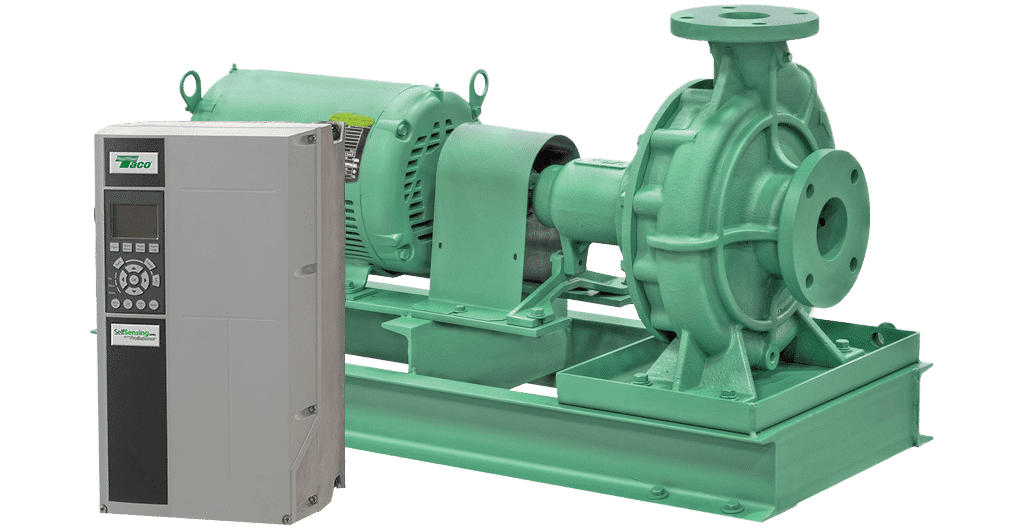

Energy-Efficient SKS Series Vertical Split-Coupled In-Line Pumps and SFI Series Base-Mounted End Section Pumps

- Easy installation and quiet, dependable performance

- Taco’s patented SelfSensing ProBalance® technology provides accurate, do-it-yourself system balancing, reducing construction costs, energy usage, and increasing pump life expectancy

- Stainless steel shaft & impeller options

- Energy efficient, ECM motor options from 3HP – 60HP, providing longer service life, lower maintenance costs and lower operating temperature

- Upgraded seals including dielectric fluid-ready Ni-Resist/Viton seals

Dependable Plate & Frame Heat Exchangers

- Designed and built to ASME standards

- High-strength, corrosion resistant

stainless steel frame plates - High-strength, corrosion resistant

stainless steel heating plates - Optional dielectric fluid-ready Viton gaskets

4900 Series High-Efficiency Micro-Bubble Air & Dirt Separator

- Patented PALL Ring technology provides superior air and dirt separation

- Designed and built to ASME standards

- BAS-friendly automatic blow-down valve

- Durable stainless steel construction

- A convenient clean-in-place (CIP) system reduces maintenance costs and downtime

- Optional on/off style Neodymium magnet assembly

We are YOUR PARTNER in collaboration for your specific job requirements

Space Constraints

The right tanks for your needs

Performance Validation (CFD)

Simulation results for performance assurance

Delivery

The right solutions at the right time

Building the best-fabricated products in the industry!

Taco’s fabrication facility located in Fall River, Massachusetts – USA, manufactures ASME Section VIII Div. 1, ISO 9001, and NSF-61 certi ed products. We design, fabricate and test both custom and standard heat transfer units, expansion tanks, air & dirt separators, hydraulic balancers, and other specialized pressure vessels.

The engineering capabilities of our ASME dedicated design team extend even further, fulfilling custom requests to meet unique requirements. Our capabilities and streamlined manufacturing process allow us to provide quality products and fast, flexible lead times – even emergency replacements.

With equipment in-house, our capabilities include:

20 Ton

Lifting

1 ¼"

Plate Rolling

5"

Steel Cutting

2 ½"

Stainless Steel Cutting

Unmatched

Welding Precision

Looking for more information?

Taco is a people company that understands the value of solid working relationships backed with design assistance and support for the life of the system. We are here before, during, and after your project to help you bring your systems up to peak efficiency as quickly and economically as possible. We do business with a personal touch because we believe that your personal success is as important as the success of the project.

Taco Comfort Solutions

Service & Support