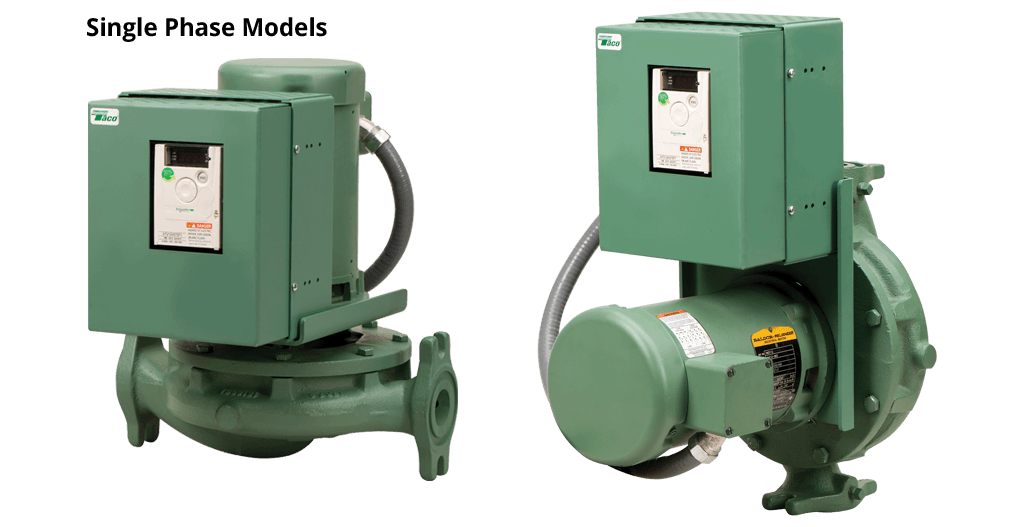

1900 VFD Series Close-Coupled In-Line Pumps

Performance Data

Flow Range: 10 – 270 GPM

Head Range: 50′ – 160′

Working Pressure: 175 PSI in accordance with ASA B16.1

Temperature: 250°F Standard, 300°F with Hi-Temp Seal

HP: ¼ – 7.5

Sizes: 1 ” – 2″

Features

- High-Efficiency Premium Motors, Available in Single Phase and Three Phase Models

- Allow Serial Communication with Pump

- Simple Selection of Drives

- Factory Preset Motor Rotation

- Robust Adjustable Bracket Design

Applications

- LoadMatch®Systems

- Air Conditioning Systems

- Recirculation

- Booster Service

- Heating Systems

- Laundry Equipment

- Cooling Towers

- Golf Courses

- Dry Cleaning Plants

- Livestock Watering

- Bottle Washers

- Lawn Sprinklers

Taco Comfort Solutions

Service & Support