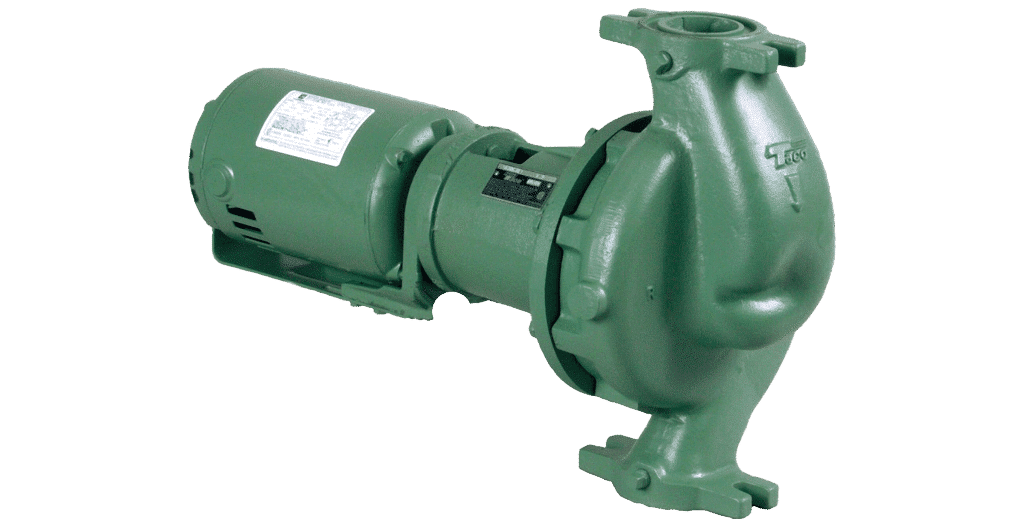

1600 Series In-Line Pumps

Performance Data

Flow Range: 20 – 200 GPM

Head Range: 10′ – 68′

Working Pressure: 175 PSI with cold water, 125 PSI at rated temperatureTemperature: 250°F Standard, 300°F with Hi-Temp Seal

HP: ¼- 3

Sizes: 1 ½” – 2″

Features

- Cartridge Assembly

- One Piece Enclosed Impeller

- Cupro-Nickel Shaft Sleeve

- Standard Mechanical Seal

- Flexible Coupler

- Resilient Mounted Motor

Applications

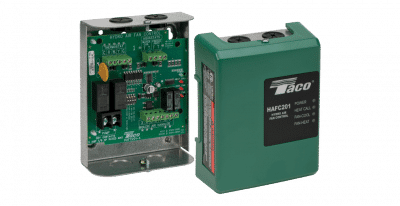

- LoadMatch®Systems

- Air Conditioning Systems

- Recirculation

- Booster Service

- Heating Systems

- Laundry Equipment

- Cooling Towers

- Golf Courses

- Dry Cleaning Plants

- Livestock Watering

- Bottle Washers

- Lawn Sprinklers

Taco Comfort Solutions

Service & Support